| Glass Printing Overview/Summary |

|

|

Digital ceramic printing on glass is a technological development used for the application of imagery, pattern or text to the surface of flat glass. Like other printing on glass methods, it is considered a form of printmaking. Although it was once only applied by traditional screen printing methods, rapid development of printing technology as made glass printing more versatile and sophisticated. Whether it's transferring an image via decal, or printing using UV inks or ceramic inks, the article below will walk you through the processes, pro and cons, and applications of the newest forms of glass printing.

|

| Printing Onto Glass Methods

|

|

|

There are four major techniques to print an image onto glass.

| Traditional Silk Screen Printing |

Water-Slide Transfer Decals (also called slip decals) |

Digital Printing using UV Curable Inks |

Digital Printing using Ceramic Ink |

| A mesh stencil is used to apply the ink to the glass surface. |

A graphic is printed on a special type of transfer paper, which creates a transparent film of the graphic when activated by water. This film is then pressed onto the glass or ceramic, then heated to complete the bonding process. |

Similar to inkjet printing. After the ink is dropped onto the surface of the glass, they are then exposed to ultraviolet waves to dry them to the glass. |

Similar to inkjet printing, the printer head releases tiny drops of ink that fall onto the glass surface where they mix to create variety of colors. |

| Limited up to 3 colours, high ink wastage, low printing accuracy. |

Is also sometimes broadly called “digital ceramic printing” or DCT. |

Allows for any digital image to be printed with a larger range of colors and details. |

The ink is made with inorganic pigment that can withstand the tempering process. |

| Needs to be fired to permanently infuse the ink with the glass. |

Needs to be either fired in the oven, or dried by a hair-dryer or heat gun to completely cure before the top layer of film is removed. |

Ultraviolet waves hardens the ink and creates a solid coating to seal the pigments to the material. |

Similar to traditional silk screen printing, the ink here must also fired. Usually the printed image is slid through a firing bed that reaches by using a tempering process that reaches over 980 degrees centigrade. |

| Fired-ceramic colors become part of the glass permanently. |

Can print up to 1200 dpi, but limited in smaller sizes. Quality dependant on printer and applicant skill. Previously used only by professional printers, but now have been repackaged for the hobbyist or small business markets. |

Since the UV-inks are not fused to the glass with the same kind of permanence that ceramic inks are, this process is not suitable for outdoor environments, such as on automotive or architectural glass. |

Can print a variety of colors, and is possible to view the image from either side of the glass. Can print up to 720 dpi. |

|

| Traditional Silk Screen Printing

|

|

|

In this method, the ink is applied directly to the surface of the glass through a mesh stencil. The ink is then permanently infused to the glass by firing it in a kiln. This method has been used the longest in history, but has a very high set-up time. Screens have to be purchased, maintained and stored, and since each color is applied through one stencil, the final image is limited to up to 3 colors. Thus, its printing accuracy is quite low.

|

An example of the screen printing process, with the template on top and the glass underneath.

|

| Water-Slide Transfer Decals

|

|

|

Water-slide decals (or slip decals) are a type of transfer decal that bind the graphic to a substrate (such as glass or ceramic) via a layer of dextrose corn sugar residue that is activated by water. To better visualize this process, imagine how a temporary tattoo is adhered via a sheer, sticky film. After the image is stuck onto the surface, the inks are cured by a heat gun or an oven to permanently bond the inks to the substrate.

Although the process varies depending on the brand of transfer paper, this is a general overview how the water-slide transfer decals work in concept:

- The graphic is printed on transfer paper (either by a laser or inkjet printer).

- The thin film of corn sugar traps and contains the printed ink and holds it together. Depending on the brand or process, the image may need to sprayed with an aerosol covercoat to completely seal it.

- ATo activate corn-sugar film, the paper is soaked in water. This will help soft the film so it is easier to separate from the paper when the decal is applied to the substrate surface.

- The decal is placed in position on the glass or ceramic. At this point, the film should be solid enough that the paper backing can slide out from under it smoothly and easily.

- A squeegee, rubber roller or sponge is then applied to remove the excess water.

- The film is then dried with a blow-dryer, kiln or an oven.

Although initially this process was only used by professional printers, the transfer papers have now been repackaged for the hobbyist/diy market as well. To increase versatility and use, transfer papers are available for both inkjet printers and laser printers alike. This makes water-slide transfer decals a less expensive way to experiment with a variety of products, or an occasional gift.

|

The water activates the decal's transparent chemical composition, and holds the inks in place.

The decal can be slid onto the glass or ceramic and then fired into place. When dried, the decal's top film becomes solid and peels off cleanly.

|

| Digital Printing Using UV Curable Inks

|

|

|

UV printing is a form of digital inkjet printing that uses ultraviolet rays to cure ink instead of firing it. When the inks are fully cured, they create a strong coating that adheres the inks to the surface of the media. Because inkjet heads can create colors more accurately from the data in the digital file, this method of printing allows for wider array of colors with shorter set-up times. The final result is extremely scratch-resistant and chemically resistant. This method is mostly used to produce smaller applications such as smartphone cases, packaging labels, key-fobs, etc. It is also the printing method of choice for beer bottles in particular, as the inks are easier to remove, allowing more glass to be reused when recycled.

Although it is scratch-resistant, the coating can ultimately be chipped or snapped off. Therefore, this method of glass printing is not suitable for outdoor environmental use.

|

UV Ceramic Ink printing is the most popular choice for glass packaging.

UV Ceramic Inks harden on the surface of the glass, making the glass more easily recyclable and an eco-friendly option.

|

| Digital Ceramic Ink Printing Process

|

|

|

At the most advanced level, digital glass printers, ceramic inks, and image processing software are fully integrated with one another, allowing much higher precision, control and flexibility in manipulating transparency, translucency, opacity, and color matching.

In this process, a flatbed digital printer jets a special kind of ink directly onto the glass. This ink is made with ultra-fine ceramic particles, pigments and elements. They dry immediately upon dropping onto the glass, and adhere permanently to the glass once cured. Unlike other glass printing processes, the kiln is built into the processing stream, so that the sheet of glass is printed and cured all on the same belt. The final result is extremely scratch and weather resistant, and the precision in the inkjet technology allows for a wider gamut and fuller display of colour.

Like the UV-ink process, the glass and pigments are fully recyclable and environmentally friendly. The inks are non-toxic, metal-free and do not contain lead or cadmium.

Make sure your shipping tube is 4-inches longer than the shortest side of your artwork. Allow for 4 to 5 inches of padding on each side of the rolleed art.

|

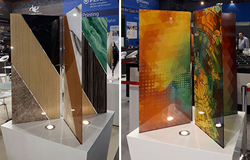

An example of a direct-to-surface glass printer with ceramic inks.

|

| Applications in Glass Printing

|

|

|

Glass and ceramic printing is fast becoming a new and popular way to print on demand for artists and photographers. Digital ceramic printing technology can be applied to create custom home decor items and gifts such as:

- Mugs

- Plates

- Glassware

- Coasters

- Tiles

- Backsplashes

- Flooring

- Furniture

Glass printing can also be found outdoors. Due to its scratch-resistance and permanence, it is weather-proof and excellent for:

- Signage

- Advertisements

- Architectural designs

- Interior design

- Tiles

- Automobile decor

- 3D Public art

- Building facades

- Doors and windows

In the case of utilizing glass in architectural design, colored graphics on glass prevent birds from crashing into windows, which is common problem for modern skyscrapers and buildings. The same graphics also mitigate reflected heat, as well as control light diffusion and transmission.

|

Printed glass panels can be used for interior design and exterior surfaces, as well as signs.

These glass coasters were made by silk-screening on glass

|

| Beyond Glass

|

|

|

The best part of printing on glass is that most of the processes involved allow printing on curved surfaces, which open up a wide range of choices depending on your needs. In addition, the printing processes described above can also apply to various other materials, such as ceramic, wood, stone, plastic, metal, etc. Any of these processes would be great for rapid prototyping.

|

| Comparison to Dye-Sublimated Printing

|

|

|

With print technology rapidly evolving, there can be many similar overlaps from one to another. Dye-sublimation technology is one of the most popular ways to print onto unconventional glossy material, such as mugs or metal, which can achieve a similar look to glass or ceramic printing. Below are some of the similarities and differences between Dye-Sublimated Printing and the general process of printing onto glass:

| Dye-Sublimated Process |

Similarities |

Glass/Ceramic Printing |

| Transfer paper is required for all dye-sublimated products. |

Use of transfer paper involved. |

With ceramic/glass printing, there is also a direct-to option that does not require transfer paper. |

| The heat of the heat press transforms the inks from liquids to gaseous forms, which permeate the coating permenantly. |

Must be exposed to extreme heat to cure coating or inks. |

The inks remain in liquid form as they are applied, but solidfy into ceramic after being baked in kiln or oven. |

| The final outcomes is considered on of the most durable products. |

Final products are scratch-resistant and chemically resistant |

Silkscreen and UV-inks are scratchable and can flake off. |

| Dye-sublimated images must only transfer on material that has been specially coated with the polymer-coating, in order to receive the inks properly. This can be polyster-based fabric, mugs, wood panels, etc. |

Final products are scratch-resistant and chemically resistant |

With ceramic/glass transfer printing method, virtually any graphic can be placed on substrate, both transparent and opaque. However, it has to be able to withstand the heat of the curing process. |

If you are looking to have an image put onto a mug, metal, or wood, KeenArt can help with our dye-sublimated services. Dye-sublimated prints take shorter production times and are faster to make to achieve the same look as ceramic or glass printing.

|

|

If you are looking to have an image put onto a mug, metal, or wood, KeenArt can help with our dye-sublimated services. Dye-sublimated prints take shorter production times and are faster to make to achieve the same look as ceramic or glass printing (we print on mugs here). We can also create your images onto wood, metal, or fabric. Upload your graphic today and get your print in as early as 5 business days!

|

|

|

Custom-Made Picture Framing, Custom Stretcher Bar Frames

, Custom Artist Canvas, Custom Canvas Stretching, Canvas transfer & Dry Mounting Services

A division of USA On Canvas -

|

|

© 2002-2026 - KeenART Media Ltd.

|

|

| |

|